Three-way Valves----Precise Control of Media Flow Enhances System

As heat pump technology expands in heating, cooling, and hot water applications, three-way valves have emerged as critical control components in heat pump systems.

I. Core Functions of three-way Valves: Multi-Scenario Media Flow Control

Heating and Domestic Hot Water Mode Switching

In gas-fired boilers or air-source heat pumps, three-way valves use motor-driven valve cores to intelligently switch between heating water and domestic hot water circuits. For example, when hot water is demanded, the valve closes the heating circuit and diverts water to a plate heat exchanger for heating tap water. After use, it restores the heating circuit, ensuring stable indoor heating. This function resolves conflicts between heating and hot water supply, improving energy efficiency by 15%-20%.

Precise Refrigerant Flow and Direction Control

In central air conditioning or heat pump units, three-way valves regulate refrigerant distribution between evaporators, condensers, and bypass branches, enabling flexible switching between cooling and heating modes. For instance, in low-temperature environments, valves can direct refrigerant to auxiliary heating modules, enhancing heat pump performance and overcoming heating deficiencies. A heat pump model optimized with three-way valves maintains a COP ≥3.0 at -15℃.

Anti-Backflow and Heat Loss Prevention

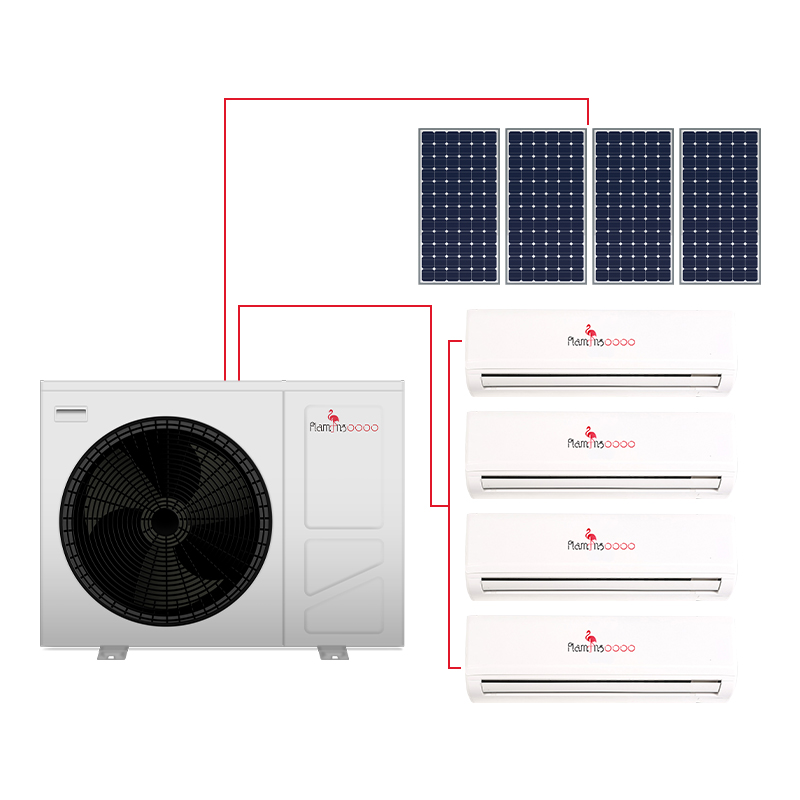

In solar-coupled heat pump systems, three-way valves, linked to temperature sensors, block hot water from flowing back into collectors when collector temperatures are lower than tank temperatures, reducing heat loss. For example, an indirect expansion solar heat pump system using three-way valves reduces heat loss by 30% and extends equipment lifespan by preventing thermal shock to vacuum tube collectors.

II. Technological Breakthroughs: Intelligence and High Reliability

Optimized Electric Actuators

New-generation three-way valves use stepper or servo motors, achieving response times under 0.5 seconds and control accuracy within ±1%. For example, Mcville Industrial Group’s imported air conditioning three-way valves enable stepless refrigerant flow regulation, meeting variable-flow demands in multi-split systems.

Advanced Materials and Sealing Technologies

Valve bodies employ 304 stainless steel or corrosion-resistant alloys, while valve cores and seats use hard alloys or ceramic coatings, enhancing wear resistance by 50%. For instance, a domestic three-way valve using nano-coating technology extends valve core sealing lifespan to over 100,000 cycles with leakage rates below 0.01%.

Intelligent Diagnostics and Self-Cleaning Functions

High-end valves integrate pressure sensors and flow meters for real-time monitoring. For example, when detecting valve core jamming or poor sealing, systems automatically initiate reverse flushing to remove impurities, reducing maintenance costs.

III. Application Cases: three-way Valves Boost System Efficiency

Auxiliary Heating Air-Source Heat Pump Systems

In a northern residential project, an auxiliary heating air-source heat pump with three-way valves maintained indoor temperatures above 20℃ at -20℃, reducing energy consumption by 25% compared to traditional solutions.