Key Installation Details for Ground-Source Heat Pump Systems

Scientific Planning and Precise Construction Ensure High-Efficiency Operation

As China advances its "dual carbon" strategy, ground-source heat pump (GSHP) systems are gaining popularity in residential, commercial, and industrial sectors due to their energy efficiency and environmental benefits. However, installation quality directly impacts system performance, lifespan, and reliability. Industry experts have summarized critical installation details based on real-world projects to guide practitioners.

I. Preliminary Survey and Design: Tailored Solutions to Mitigate Risks

Geological and Hydrological Assessment

GSHP systems require sufficient water sources with qualified water quality (e.g., suspended solids ≤50mg/L, sediment content ≤1/200,000). For insufficient water sources, hybrid systems (e.g., water source + cooling tower) can be adopted. Poor water quality necessitates pre-treatment equipment such as sand filters or reverse osmosis units.

Case Study: A northern project failed to test groundwater hardness, leading to severe scaling in heat exchangers and a 30% efficiency drop. Performance was restored after installing a water softener.Load Calculation and Equipment Selection

Accurate cooling/heating load calculations based on building type (e.g., residential, hotel, factory) are essential to avoid oversizing. For example, a hotel project with oversized equipment led to 25% higher energy consumption due to prolonged low-efficiency operation.System Layout Planning

The machine room should be located near water wells or ground loop fields to minimize pipe length. Maintenance space (e.g., 1.2m clearance around the host unit) must be reserved.

II. Installation and Construction: Standardized Operations for Quality Assurance

Ground Loop Heat Exchanger Installation

Borehole Depth and Spacing: Vertical boreholes are recommended at 80-150m depth with 4-6m spacing to prevent thermal interference.

Backfill Material: High-thermal-conductivity fine sand or specialized backfill materials enhance heat transfer efficiency.

Pressure Testing: A 0.8MPa hydrostatic test must be conducted post-installation, with 24-hour pressure retention to ensure no leaks.

Water Well Construction

Well Depth and Flow Rate: Single wells are typically 80-150m deep, with flow rates meeting host unit demands (e.g., 0.5m³/h per 10kW cooling capacity).

Anti-Siltation Measures: Install sediment traps at the well bottom and filters at the wellhead, with regular well wall cleaning.

Pipe Connection and Insulation

Welding and Corrosion Protection: Steel pipes require anti-corrosion treatment (e.g., epoxy coating) after welding.

Insulation Thickness: Select insulation thickness based on ambient temperature (e.g., ≥50mm rubber-plastic insulation in northern regions).

Electrical and Control System Installation

Power Supply Configuration: Dedicated cables are required for high-power host units (e.g., 16mm² copper cables for 30kW units).

Smart Control: Install temperature/humidity sensors, flow meters, and remote monitoring systems for energy optimization.

III. Commissioning and Acceptance: Rigorous Testing for Performance Assurance

System Flushing and Air Exhaust

Post-installation, pipes must be flushed (flow rate ≥1.5m/s) to remove impurities, and air must be exhausted via automatic air vents.Performance Testing

Heating/Cooling Efficiency: Must exceed 90% of design values (e.g., COP ≥4.0).

Water Temperature Fluctuation: Should be controlled within ±2℃ during operation.

Acceptance Criteria

Inspections must comply with Technical Code for Ground-Source Heat Pump System Engineering (GB 50366-2005), focusing on pipe sealing, electrical safety, and energy efficiency metrics.

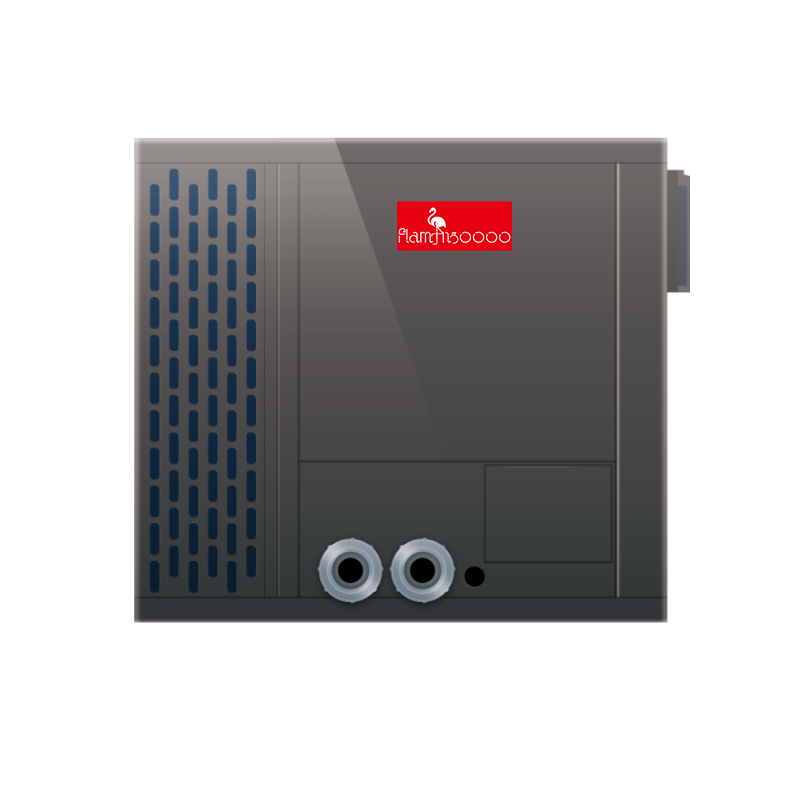

IV. Future Trends: Intelligence and Integration

With IoT advancements, GSHP systems will evolve toward "intelligent operation + multi-energy integration." For example, AI algorithms predict load variations to adjust host unit output automatically, or integrate with solar and energy storage systems for enhanced efficiency.