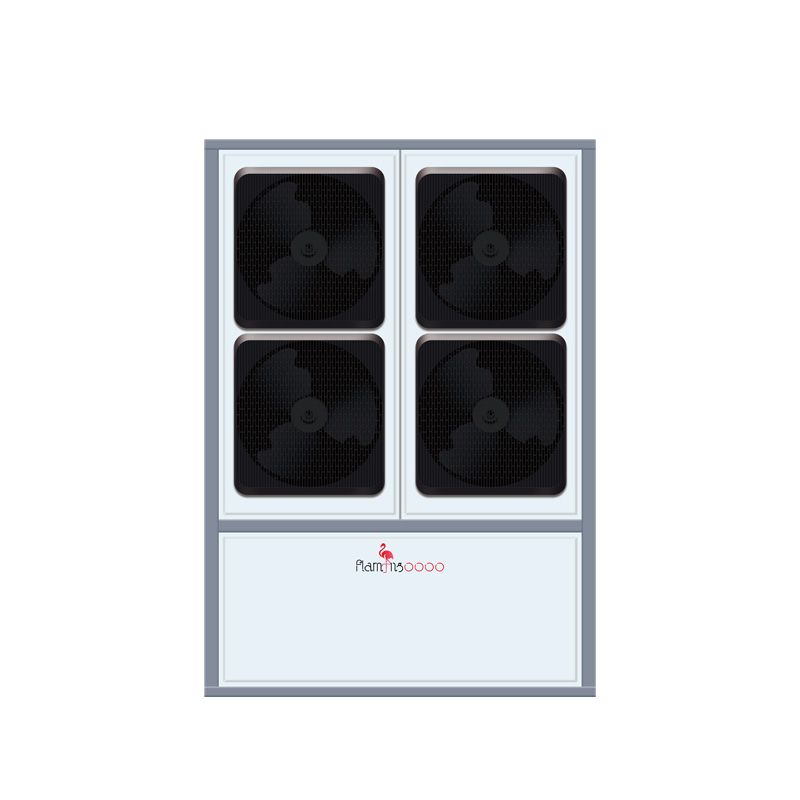

Key Functions of Buffer Tanks

Reducing Frequent Starts/Stops of the Host Unit, Extending Equipment Lifespan

Traditional HVAC systems often experience rapid temperature fluctuations due to insufficient water circulation, leading to frequent starts/stops of the host unit and increased wear. Buffer tanks store thermal energy, stabilizing temperature changes and reducing start/stop cycles. For example, in northern winter heating, installing a 150L buffer tank can reduce host unit starts/stops by over 40%, extending its lifespan by 3-5 years.Efficient Defrosting, Enhancing Heating Comfort

Frost formation on air-source heat pumps in low temperatures significantly impacts heating efficiency. Traditional systems consume heat from pipes during defrosting, causing indoor temperature drops. Buffer tanks store heat, enabling rapid heat supplementation during defrosting. Tests show that systems with buffer tanks can complete defrosting in under 5 minutes, with indoor temperature fluctuations controlled within ±1℃.Automatic Air Exhaust and Sewage Discharge, Ensuring System Safety

Air and impurities in water circulation systems can cause pump cavitation and pipe blockages. Buffer tanks adopt a "top-in, bottom-out" design, allowing air to accumulate at the top and be discharged via an exhaust valve, while the bottom outlet ensures no air enters the pump, preventing malfunctions. Impurities settle at the tank bottom, reducing Y-type filter cleaning frequency and maintenance costs.Stabilizing System Pressure, Improving Energy Efficiency

Buffer tanks absorb pressure fluctuations caused by temperature changes, preventing system damage from overpressure or underpressure. For instance, in summer cooling, tanks buffer pressure rises due to water temperature increases, protecting host units and pipes.

Technological Innovations and Industry Applications

Driven by market demand, buffer tank design and manufacturing technologies continue to evolve. For example, Guangdong Ruifa Electric Appliance Co., Ltd.'s "Pressurized Tank Protector" features a nano-coated 304 stainless steel liner and 316 stainless steel coil, enhancing corrosion resistance by 50% and achieving a lifespan of over 15 years. Its products, available in 20L-2000L capacities and various installation methods (circular, square, wall-mounted), are widely used in residential heating, commercial air conditioning, and industrial cooling.

Experts recommend calculating buffer tank capacity based on system cooling capacity and pipe water volume. For example, 35L of tank capacity is required per 1kW of cooling capacity, or a "universal" 100L/150L tank can be selected for most projects.

Future Prospects

Under the "dual carbon" goals, buffer tanks, as energy-saving devices in HVAC systems, will see sustained market growth. In the future, with the integration of IoT technology, smart buffer tanks will enable remote monitoring, automatic sewage discharge, and energy consumption optimization, further promoting building energy efficiency.