A Green Revolution in "Transporting" Thermal Energy from Air

Technical Principles: The "Thermal Energy Transporter" of the Reverse Carnot Cycle

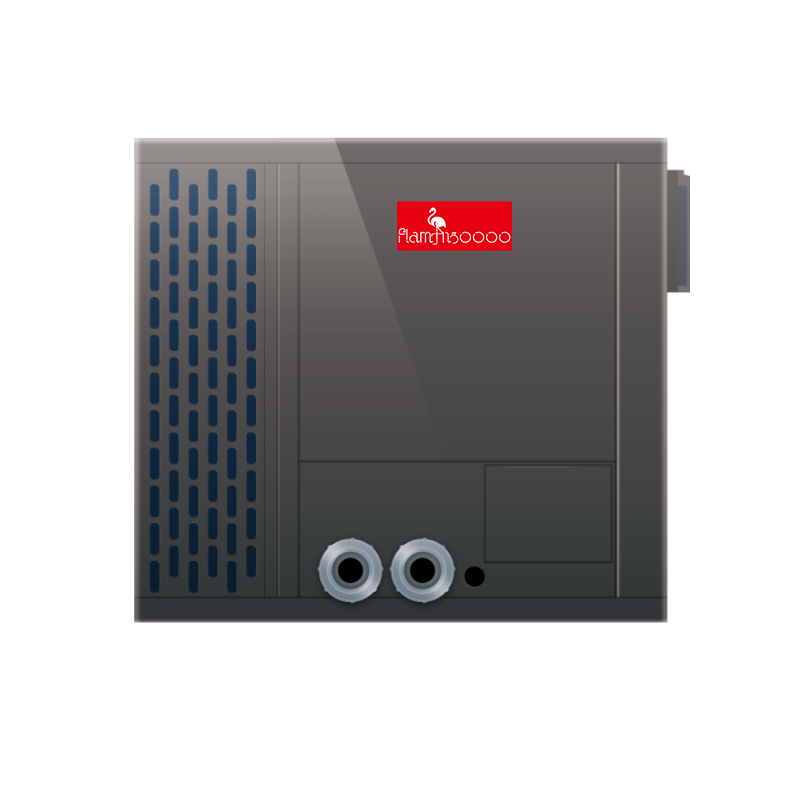

ASHPs operate on the Reverse Carnot Cycle, transferring heat from low-temperature environments to high-temperature ones through the cyclic phase changes of refrigerant in four key components: the evaporator, compressor, condenser, and expansion valve.

Evaporator Heat Absorption: Outdoor air passes through the evaporator, where the refrigerant absorbs heat and evaporates into a low-temperature, low-pressure gas.

Compressor Pressurization: The gas is compressed by the compressor into a high-temperature, high-pressure gas, with temperatures exceeding 80°C.

Condenser Heat Release: The high-temperature gas flows through the condenser, transferring heat to indoor water or air and condensing into a high-pressure liquid.

Expansion Valve Throttling: The liquid is depressurized and cooled by the expansion valve, returning to the evaporator to restart the cycle.

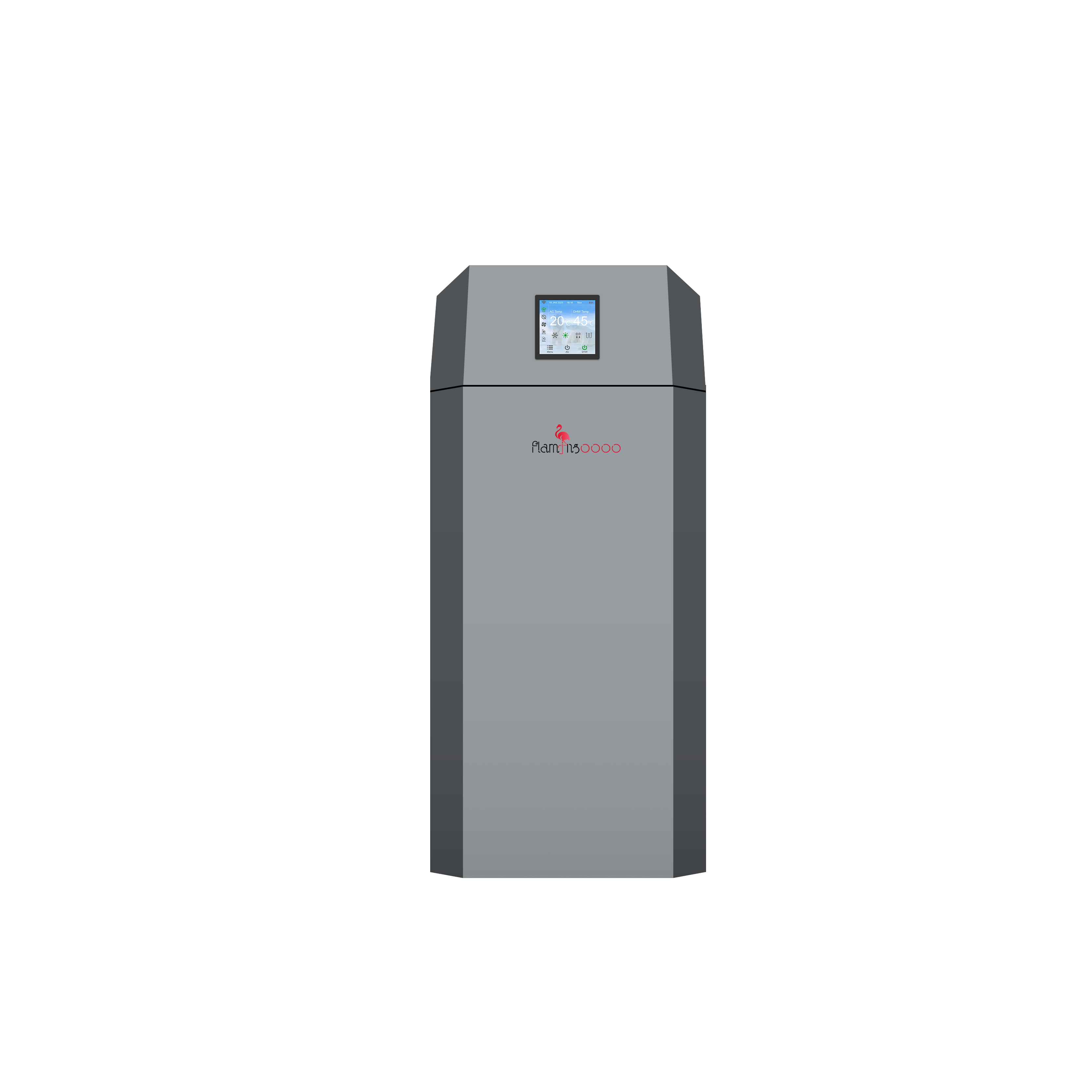

Take Micoe’s integrated ASHP system as an example: its DD-HOT "Superheat Loop" Technology and DHC Variable Frequency Heat Core enable a Coefficient of Performance (COP) far exceeding national first-tier standards, ensuring stable heating at -25°C with a heat output decline rate below 15%.

Technological Breakthroughs: Overcoming Dual Challenges of Extreme Cold and Noise

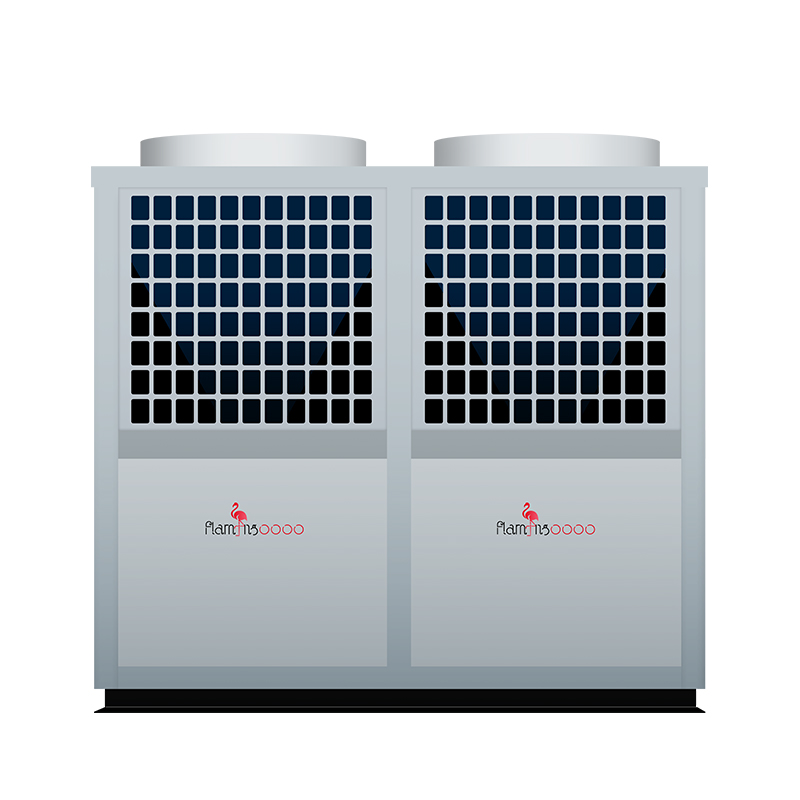

Extreme Cold Heating Technology: Traditional heat pumps are prone to frosting in low temperatures, reducing efficiency. Companies like Micoe employ Ejector Enthalpy Enhancement Technology and Full DC Variable Frequency Technology to enable efficient operation in ultra-low-temperature regions like Mohe and China’s Antarctic Great Wall Station.

Silent Design: Low-noise compressors and vibration-damping structures reduce operational noise to below 45 decibels, equivalent to library ambient sound, eliminating the "roaring" disturbances of traditional devices.

Market Applications: Green Transition from Rural to Urban Areas

Driven by national subsidies, ASHPs are rapidly gaining popularity. In Beijing, homeowner Ms. Liu’s installation of a Micoe system reduced winter heating costs by 66% compared to coal-fired boilers, with daily electricity expenses averaging just 15 yuan. By 2025, companies like New Energy have deployed over 1 million units in northern China, saving 5 million tons of standard coal annually and reducing CO₂ emissions by 10 million tons.