What Factors Cause Heat Pump Efficiency Reduction?

Hailed as a key solution to replace fossil fuel heating, heat pump technology is rapidly being deployed worldwide. However, as many installations fail to achieve theoretical efficiency levels in real-world operation, the underlying causes are coming under scrutiny.

A survey by the UK's Energy Saving Trust (EST) revealed a startling fact: 83% of installed heat pumps in the UK are underperforming, with 87% failing to meet the minimum energy efficiency benchmark of a 3-star rating.

Research by ETH Zurich, collaborating with several universities, analyzed real-world operational data from 1,023 heat pumps across 10 Central European countries. They found significant performance variations between units – under identical temperature conditions, the Coefficient of Performance (COP) gap between some devices reached 2-3 times. This finding has prompted the industry to re-examine the critical factors affecting heat pump efficiency.

01 Equipment & Installation Issues

The primary culprits for low heat pump efficiency lie in the equipment itself and installation quality. The EST survey identified disorganized industry management within the installation sector as a core problem.

Simon Green, Head of Business Development at EST, stated frankly: "When installed and used correctly, heat pump technology could significantly reduce the UK's CO₂ emissions. However, the current situation differs considerably from our estimates."

In the UK, the Heating and Hotwater Industry Council (HHIC), responsible for residential heat pump installations, publicly acknowledged a lack of sufficient manpower to help consumers choose suitable products. This absence of expert guidance leads to frequent selection errors, with users often purchasing equipment mismatched to their building's characteristics.

Equipment aging is another efficiency killer. Modern air-source heat pump manufacturers note in their maintenance guides that key components like compressors and heat exchhers wear out over time. Poor sealing causes refrigerant leaks, reducing heating/cooling efficiency, while aging electrical systems directly impact operational stability.

02 Environmental & Design Factors

Environmental conditions are the second major variable impacting efficiency. Ambient temperature decisively influences the heating efficiency of air-source heat pumps – lower temperatures lead to significantly reduced efficiency.

Installation location is equally crucial. Placement near heat sources or radiators restricts airflow, directly impairing heat exchange efficiency. Indoor humidity and air quality also create cascading effects on heating performance.

ETH Zurich's large-scale data analysis found that ground-source heat pumps achieved an average COP of 4.90, far exceeding the 4.03 average for air-source units. Crucially, ground-source efficiency is less affected by outdoor temperature fluctuations, demonstrating more stable performance.

The research also uncovered a key design flaw: approximately 7-11% of heat pump systems are oversized, while about 1% are undersized. This sizing mismatch prevents operation at optimal conditions, causing energy waste.

03 Improper Operation & Maintenance

The maintenance status of a heat pump system directly affects its long-term efficiency. Regular maintenance is key to ensuring normal operation, yet this basic requirement is often neglected in practice.

Poor upkeep can cause component clogging or damage, while non-standard maintenance methods introduce new problems. Incorrect refrigerant charge levels – whether overcharged or undercharged – significantly reduce heating efficiency. Using improper cleaning agents on heat exchangers similarly damages performance.

European research indicates that reducing the heating curve setting by 1°C can increase average heat pump efficiency by 0.11 COP and reduce household energy consumption by 2.61%. Many users are unaware of such optimization methods, leading to prolonged suboptimal operation.

Refrigerant issues are another common cause of efficiency loss. Insufficient heat-carrying capacity of the refrigerant reduces the effective heat exchange per cycle. Some manufacturers use substandard refrigerants to cut costs, or leakage occurs during transport, resulting in failure to reach design water temperatures.

04 System Configuration & Sizing Issues

Inappropriate system configuration is a deep-rooted cause of inefficiency. Heat pumps dedicated to domestic hot water (DHW) production show significantly lower COP values than those used for space heating, because DHW requires higher flow temperatures. This difference in energy demand characteristics is often overlooked during design.

Sizing problems are particularly acute in residential applications. ETH Zurich's team developed utilization metrics to assess sizing appropriateness, finding that oversized or undersized systems are remarkably common.

In industry, system integration methods critically impact overall efficiency. Studies in cement plant CO₂ capture projects show that integrating high-temperature heat pumps can reduce the incremental clinker cost by 32%. However, achieving such optimization requires precise system design and integration capabilities, posing challenges for many installers.

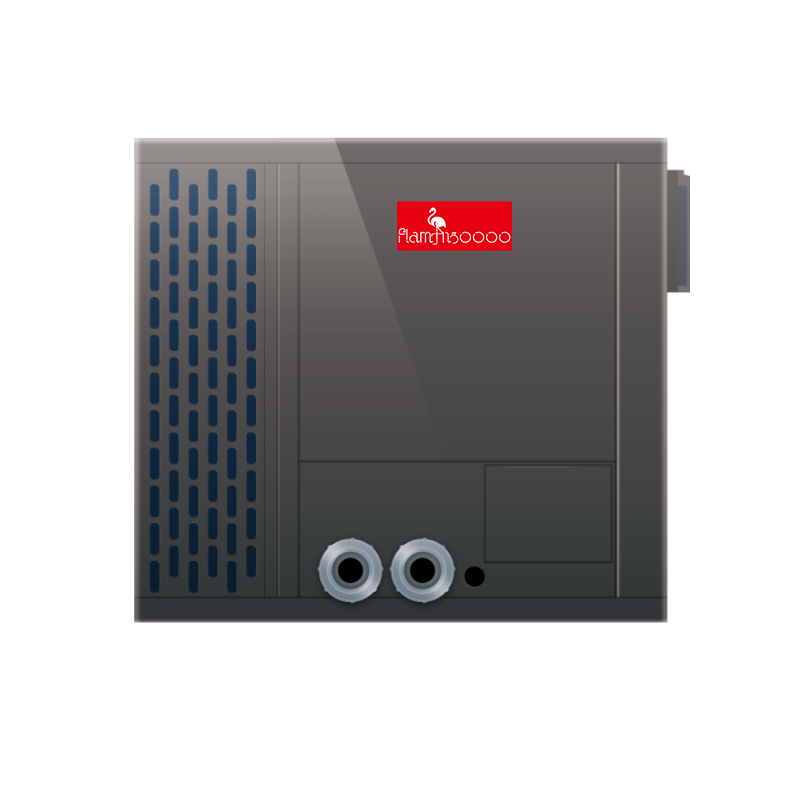

China's popular "dual-supply" systems (integrated cooling and heating) enhance overall energy efficiency through innovative design. In summer, refrigerant is distributed via wall-mounted indoor units; in winter, hot water circulates through underfloor radiant heating systems, aligning with the traditional Chinese health principle of "warm feet, cool head." Optimized configurations yield significant efficiency gains.

05 Solutions & Future Outlook

Addressing heat pump efficiency challenges requires both technological innovation and policy adjustments. A breakthrough by Hong Kong University of Science and Technology (HKUST) researchers involves Ti₇₈Nb₂₂ elastic alloy, achieving a temperature-change efficiency 20 times greater than conventional metals, reaching 90% of the Carnot efficiency limit.

This material heats and cools through elastic deformation, opening a new path for solid-state heat pump technology. The team is currently developing an industrial heat pump prototype based on this alloy.

Operational monitoring and intelligent adjustment offer practical efficiency gains. European researchers recommend establishing standardized post-installation performance assessment procedures and developing digital tools to help users optimize settings. Simple adjustments, like lowering the heating curve, yield substantial energy savings.

Policy design needs refinement. German experience shows that high electricity prices can hinder heat pump adoption. Rational adjustments to energy tax structures, making electricity more competitive against natural gas, would accelerate the replacement of fossil-fuel heating.

Industrial applications hold vast potential. Cement plant CO₂ capture projects integrating high-temperature heat pumps demonstrate the technology's ability to reduce emissions while cutting incremental clinker costs by 32%. As renewable electricity expands and high-temperature heat pump technology matures, such solutions could become core decarbonization technologies for energy-intensive industries.

The future development path for heat pump technology is becoming clearer. The Ti₇₈Nb₂₂ elastic alloy developed by HKUST material scientists performs exceptionally in the lab. Industrial fields are exploring new frontiers. Cement plant carbon capture projects combining high-temperature heat pumps with Mechanical Vapor Recompression (MVR) have reduced CO₂ capture costs to €125.9 per tonne. As these innovations move from lab to market, heat pumps will truly become a pivotal force in the global energy transition.