How Does a DC Inverter Heat Pump Work?

In the realm of energy-efficient heating and cooling technologies, DC inverter heat pumps have emerged as a groundbreaking innovation. These systems utilize advanced engineering to achieve superior performance and energy savings compared to traditional HVAC systems. Understanding the inner workings of a DC inverter heat pump unveils the secrets behind its efficiency and effectiveness in both residential and commercial applications.

Introduction to DC Inverter Heat Pumps

DC inverter heat pumps are a type of air-source heat pump that utilizes direct current (DC) technology to regulate compressor motor speed dynamically. Unlike conventional heat pumps that operate at fixed speeds, DC inverter heat pumps adjust compressor speed based on real-time demand for heating or cooling. This adaptive capability allows the system to match its output precisely to the heating or cooling requirements of the indoor space, thereby maximizing energy efficiency and comfort.

Key Components and Functionality

1. Compressor

At the heart of every DC inverter heat pump is the compressor. This component is responsible for pressurizing the refrigerant gas, which is crucial for transferring heat between the indoor and outdoor environments. In DC inverter models, the compressor motor is equipped with an inverter drive that controls its rotational speed. By varying the compressor speed, the system can modulate the heating or cooling output effectively.

2. Refrigerant Cycle

The refrigerant cycle in a DC inverter heat pump follows a standard vapor compression cycle. It begins with the compression of low-pressure, low-temperature refrigerant gas by the compressor. The compressed gas then flows through a condenser coil where it releases heat to the outside environment and condenses into a high-pressure liquid. This liquid refrigerant moves through an expansion valve, where it undergoes a phase change, turning into a low-pressure liquid or gas. The cold refrigerant then absorbs heat from the indoor air through an evaporator coil and returns to the compressor to restart the cycle.

3. Inverter Technology

The distinguishing feature of DC inverter heat pumps is their use of inverter technology to control the compressor. Traditional HVAC systems employ fixed-speed compressors that cycle on and off to maintain desired temperatures, resulting in frequent starts and stops. In contrast, DC inverter heat pumps operate more efficiently by continuously adjusting compressor speed. This modulation not only reduces energy consumption during periods of partial load but also enhances system durability by minimizing wear and tear associated with frequent cycling.

Advantages of DC Inverter Heat Pumps

1. Energy Efficiency

DC inverter heat pumps are renowned for their superior energy efficiency compared to conventional HVAC systems. By adjusting compressor speed and output in response to changing heating or cooling demands, these systems can achieve significant energy savings, particularly in climates with varying temperature conditions.

2. Enhanced Comfort

The precise control offered by DC inverter technology contributes to improved indoor comfort. These systems can maintain more stable indoor temperatures and reduce temperature fluctuations compared to traditional systems, providing a more consistent and pleasant environment for occupants.

3. Quiet Operation

Inverter-driven compressors operate at lower speeds during periods of reduced demand, resulting in quieter operation compared to fixed-speed compressors that cycle on and off. This reduced noise level is particularly advantageous in residential settings where noise pollution can be a concern.

4. Environmental Benefits

The energy efficiency of DC inverter heat pumps translates into lower carbon emissions and reduced environmental impact. By consuming less electricity to achieve heating and cooling, these systems contribute to sustainability efforts and help mitigate climate change.

Applications and Considerations

DC inverter heat pumps are suitable for various applications, ranging from residential homes to commercial buildings and industrial facilities. They are particularly effective in regions with moderate climates where heating and cooling loads vary throughout the year. However, proper sizing and installation are crucial to maximizing the performance and efficiency of these systems.

Future Trends and Innovations

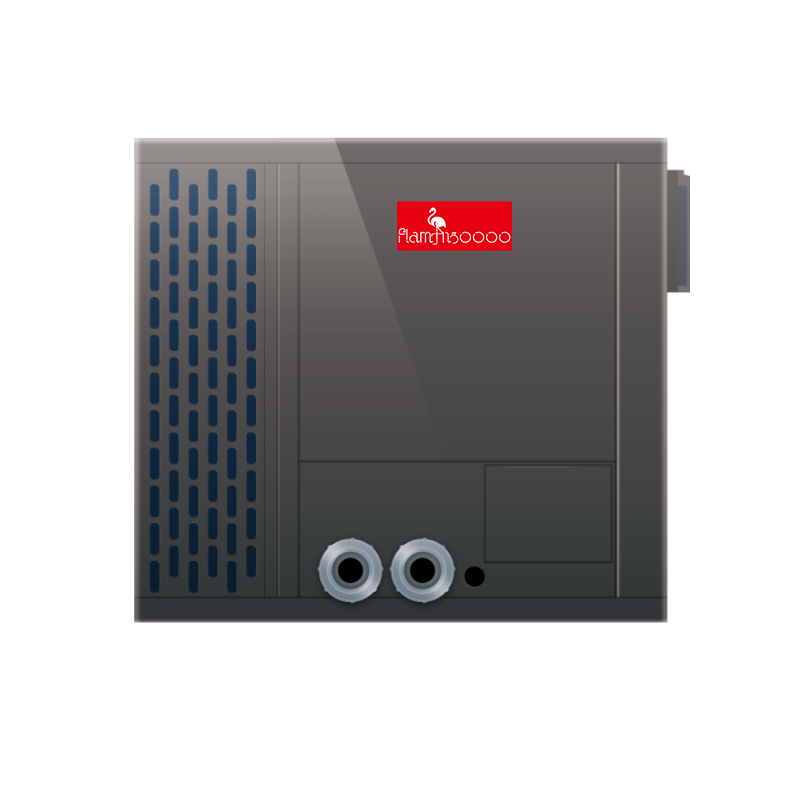

As technology continues to evolve, advancements in DC inverter heat pump design are expected to further enhance efficiency, reliability, and integration with smart home systems. Innovations such as improved control algorithms, enhanced heat exchanger designs, and integration with renewable energy sources are poised to shape the future of HVAC systems.

Conclusion

In conclusion, the operational principles of DC inverter heat pumps represent a significant leap forward in HVAC technology. By leveraging inverter-driven compressors and sophisticated control mechanisms, these systems offer unparalleled energy efficiency, comfort, and environmental benefits. As consumer demand for sustainable and cost-effective heating and cooling solutions grows, DC inverter heat pumps are poised to play a crucial role in the future of building climate control. Understanding how these systems work is essential for stakeholders in the HVAC industry, policymakers, and consumers seeking to make informed decisions about their heating and cooling needs.

Understanding the inner workings of a DC inverter heat pump unveils the secrets behind its efficiency and effectiveness in both residential and commercial applications.