Composition and Design Logic of Heat Pump Underfloor Heating System

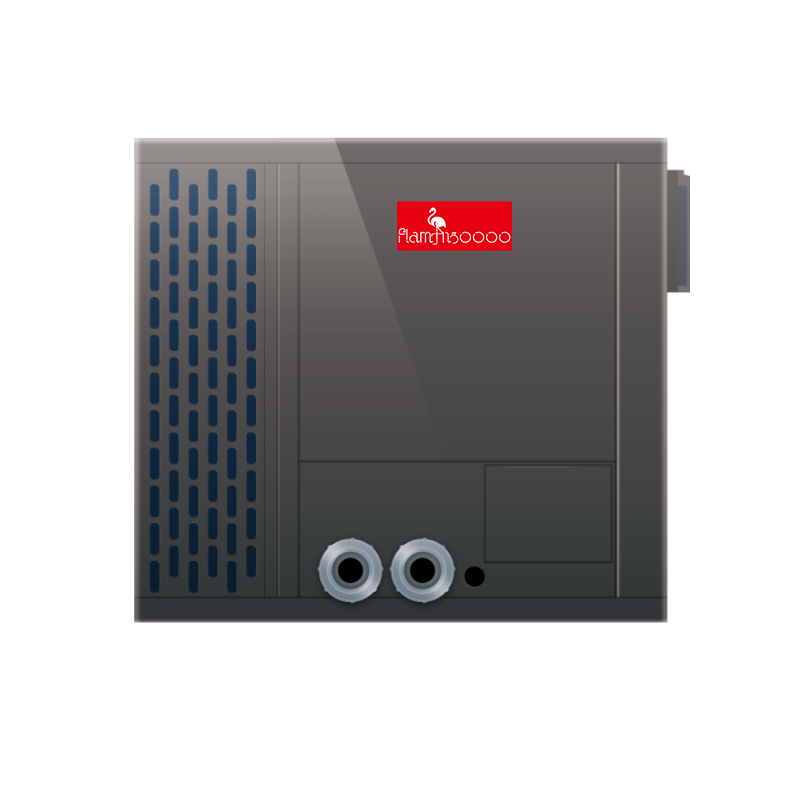

1. Heat Source and Heat Media Transportation

- Heat Source Compatibility:

- It can be connected to a central heating network, gas-fired wall-mounted boilers, air-source heat pumps, and other systems. During design, the floor heating system parameters must be adjusted based on the heat source water temperature. (If the water temperature is too high, a water mixing device must be installed to prevent overheating of the floor and scaling of the pipes.)

- Heat Media Circulation:

- A circulating pump propels hot water through the pipes, distributing it to each heating circuit via manifolds to ensure uniform flow. During design, the resistance along the pipe must be calculated to avoid overheating near the end and overcooling far away.

2. Floor heating coil layout

- Piping Methods:

- U-shaped/Spiral: The pipes evenly cover the floor, suitable for rectangular rooms, and provide uniform heat radiation.

-S-shaped/Double Parallel: Suitable for narrow and long rooms. Heat load can be controlled by adjusting the pipe spacing (e.g., 15-30cm). For areas with high heat demand, such as bedrooms, the spacing can be reduced to 15cm.

- Pipe Material Selection and Diameter:

- Commonly used PE-RT and PEX pipes are generally 16-20mm in diameter. Flow rate should be calculated based on the room's heat load (e.g., a single circuit length of 16mm pipe should be ≤80m, and a single circuit length of 20mm pipe should be ≤120m to avoid excessive resistance).

3. Optimizing heat transfer in ground structures

- Construction from bottom to top:

(1). Insulation layer (extruded polystyrene board/polystyrene board): Reduces heat loss to the floor slab, insulation coefficient ≥ 0.03 W/(m·K);

(2). Reflective film: Reflects heat upward, improving thermal efficiency;

(3). Coil securing layer (cardin/wire mesh): Secures the coils and evenly distributes heat;

(4). Filling layer (pebble concrete): Wraps the coils and serves as the primary heat transfer medium (thermal conductivity ≥ 1.2 W/(m·K)), approximately 5-7 cm thick;

(5). Finishing layer: Tiles/flooring (heat transfer efficiency: tiles > engineered wood flooring > solid wood flooring). Consider the thermal resistance of the finishing layer during design (for solid wood flooring, increase the water temperature or reduce the tube spacing).

4. Temperature and flow control

- Thermostat + Electric Valve: Installed in each manifold circuit, this automatically adjusts water flow based on indoor temperature, achieving room-specific temperature control (e.g., 20°C in the bedroom and 22°C in the living room).

- Water Mixing Device: When the heat source water temperature is too high (e.g., 70°C for central heating), cold water is mixed in to reduce the floor heating water temperature to 40-60°C, preventing high temperatures from damaging pipes or causing floor deformation.