CO₂ Heat Pumps Driving a New Era of Industrial Waste Heat Recovery in Europe

As Europe accelerates its transition toward a low-carbon energy system, industrial waste heat recovery has emerged as a critical yet underutilized resource. Across manufacturing sectors, vast amounts of thermal energy are generated as a byproduct of industrial processes and released into the environment. CO₂ heat pumps—also known as R744 heat pumps—are increasingly recognized as a key technology capable of transforming this lost energy into a valuable and sustainable heat source.

Industrial facilities such as food processing plants, chemical factories, data centers, paper mills, and metal processing sites generate significant volumes of waste heat at temperatures typically ranging from 20°C to 60°C. Traditionally, this low- and medium-grade heat has been difficult to reuse efficiently and has often been dissipated through cooling towers or ventilation systems. CO₂ heat pumps enable industries to capture this waste heat and upgrade it to useful temperature levels, frequently exceeding 90°C, making it suitable for space heating, industrial processes, and domestic hot water production.

The technical advantage of CO₂ heat pumps lies in the unique thermodynamic properties of carbon dioxide as a refrigerant. Operating in a transcritical cycle, CO₂ systems maintain high efficiency across a wide range of operating conditions. Unlike conventional heat pumps, their performance does not significantly deteriorate at higher output temperatures. This makes CO₂ heat pumps particularly well suited for industrial applications where stable and high-temperature heat supply is required.

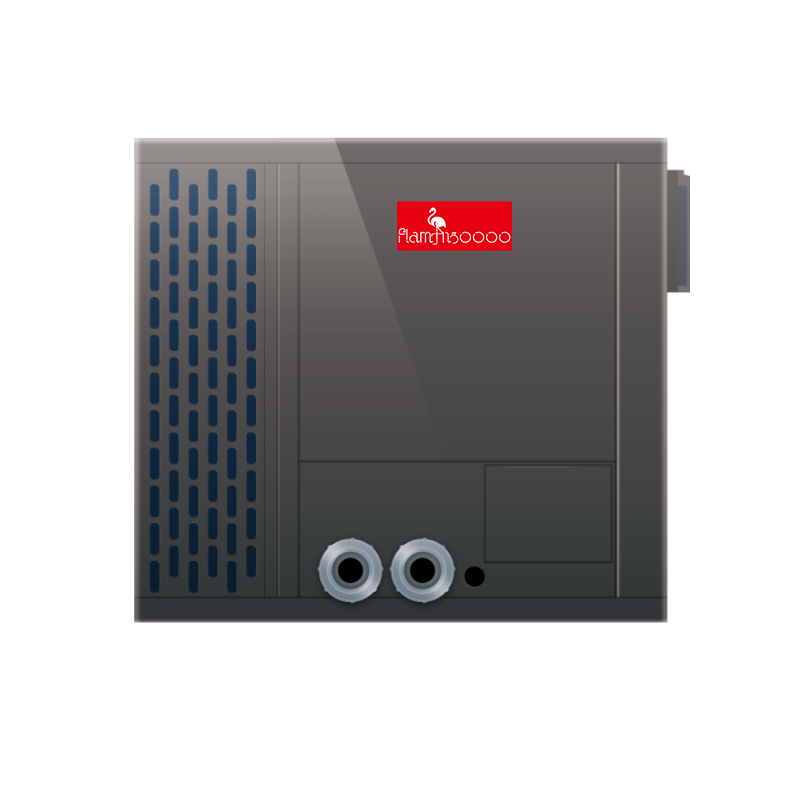

From a system integration perspective, CO₂ heat pumps offer exceptional flexibility. They can be connected to various waste heat sources, including refrigeration systems, process cooling circuits, air compressors, and wastewater streams. In many cases, CO₂ heat pumps can be integrated into existing industrial infrastructure with minimal disruption, enabling phased decarbonization without compromising operational continuity.

Environmental performance is another decisive factor driving adoption. CO₂ has a global warming potential (GWP) of 1 and zero ozone depletion potential, making it fully compliant with current and future European F-gas regulations. As regulatory pressure on synthetic refrigerants intensifies, industries are increasingly seeking long-term, regulation-proof solutions. CO₂ heat pumps provide this security while simultaneously reducing indirect emissions through higher energy efficiency.

Policy frameworks such as the EU Green Deal, the Fit for 55 package, and national industrial decarbonization programs are further accelerating market uptake. Financial incentives, carbon pricing mechanisms, and energy efficiency mandates improve the economic feasibility of waste heat recovery projects. In parallel, rising energy costs are strengthening the business case for investments that reduce fuel consumption and increase energy resilience.

By deploying CO₂ heat pumps, industrial operators can significantly reduce reliance on fossil fuels, lower operating costs, and stabilize heat supply in an increasingly volatile energy market. Beyond immediate energy savings, these systems contribute to long-term sustainability strategies by improving overall energy efficiency and supporting corporate climate targets.

As Europe continues to prioritize electrification, energy efficiency, and circular energy systems, CO₂ heat pumps are becoming a cornerstone technology for industrial waste heat recovery. Their ability to convert unused thermal energy into high-value heat positions them as a critical enabler of Europe’s industrial transformation toward a low-carbon future.